Breweries that rely on manual data collection face considerable challenges in new product development due to human error, delayed issue detection, and limited accuracy. Without real-time monitoring, inconsistencies during critical stages like mashing and fermentation can compromise quality and hinder R&D efforts to drive innovation efficiently. Breweries today face mounting pressure to innovate and deliver personalised experiences while maintaining consistent product quality.

Challenges

➤ Limited Traceability

➤ Ineffective Decision-Making

➤ Absence of Real-Time Monitoring

➤ Lack of Accuracy and Consistency in critical parameter

➤ Restricted Insights into Experimental Batch Performance

➤ Difficulty in Maintaining Consistent Product Quality

Client

A global leader in premium spirits, beer, and wine, renowned for its rich portfolio of the world’s most iconic brands. At the forefront of shaping India’s evolving social and drinking culture, the company is committed to sustainable and responsible business practices while driving innovation.

With a strong focus on quality and craftsmanship, it continuously sets industry benchmarks. The company actively supports local communities, champions diversity, and leads initiatives in water stewardship and responsible drinking, reinforcing its position as a trusted industry leader.

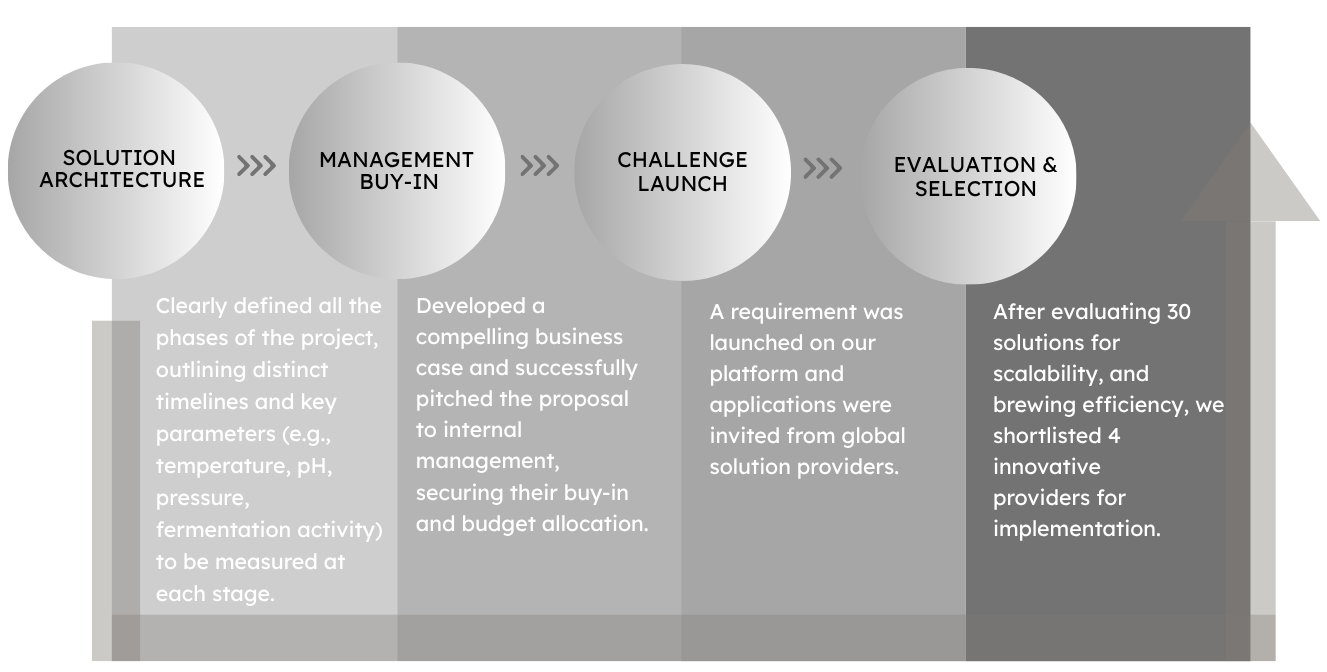

OpenI’s 4-Step Journey from Idea to Implementation

We conceptualised and materialised this idea in a span of 3 months.

Targeted Solutions Through Precision Testing & Smart Analytics

We deconstructed the problem into 3 smaller requirements – Wort Testing, Fermentation Testing & AI-based IoT software for data analytics.

After running these challenges and evaluating sensor companies, 3 companies were shortlisted for their respective fields.

- Sensors monitoring the fermentation process to determine the physical as well as chemical properties of the wort. This include Caustic Concentration, Yeast (Count, Culture etc), Temperature, Specific Gravity, pH, Alcohol by volume, various acid and mineral levels.

- Sensors continuously assessing the physical as well as chemical properties of the wort. This includes Grist Ratio, Turbidity, Specific Gravity, Temperature, pH, fermentable sugar levels and various acid and mineral content.

- An IoT platform collecting data generated by the sensors to provide insights and flag anomalies.

The Impact of Data-Driven Monitoring

Implementing automated monitoring systems by integrating IoT devices and sensors enabled real-time data collection, reduced errors, and enhance consistency. Sensors facilitated seamless tracking of critical parameters across production stages, while data analytics and predictive tools supported R&D efforts to drive innovation in product development.