Revolutionising Quality Control with AI-Powered Defect Detection

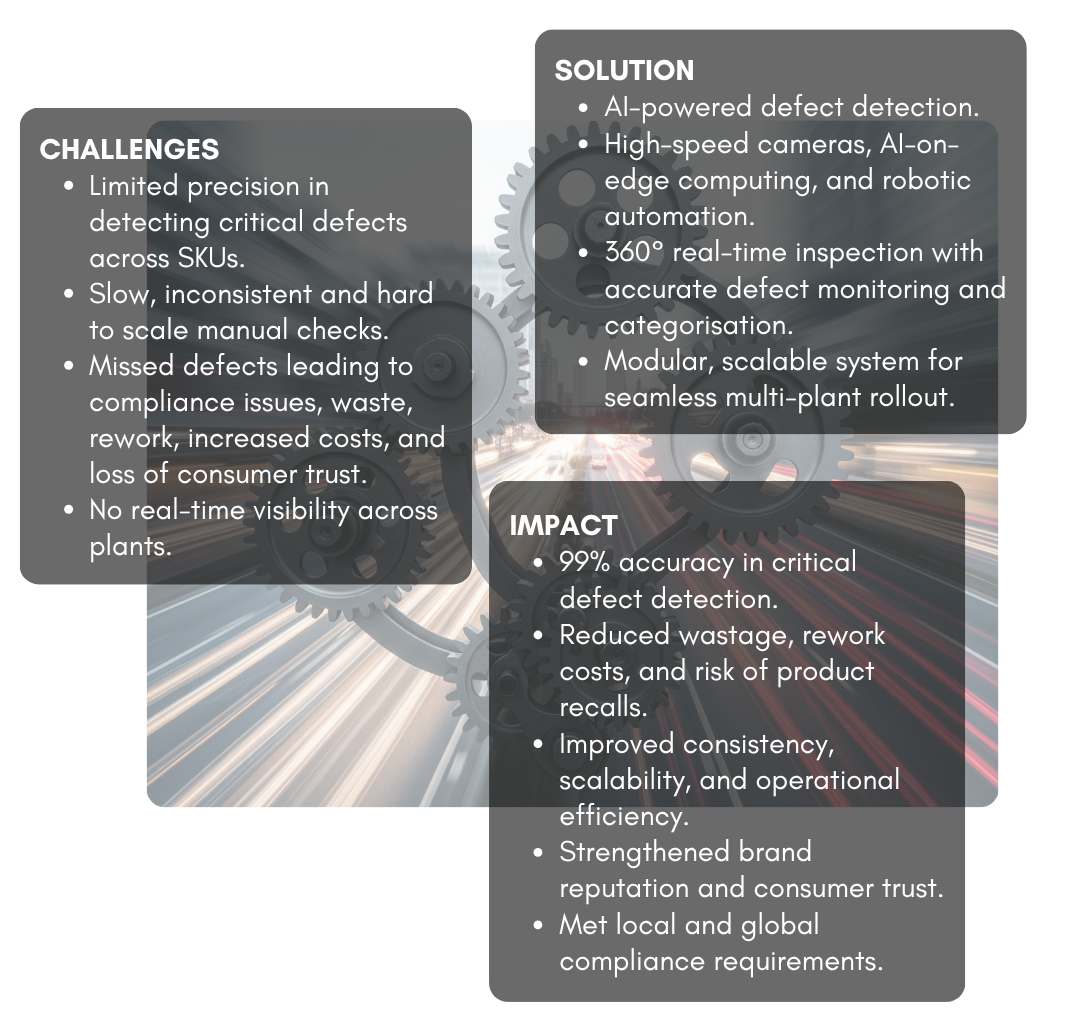

A leading global alcohol beverage company transformed their quality assurance process, achieving 99% accuracy in detecting critical defects through innovative startup-driven solutions to solve manual inspection issues creating significant operational challenges.

Key Objectives

- Automate inspection of liquids, bottles, closures, labels, and packaging.

- Improve accuracy, consistency, and scalability of defect detection across SKUs.

- Enhance real-time visibility into defect trends and enable full coverage.

- Reduce wastage through early defect identification.

- Establish scalable systems for multi-plant rollout and operational efficiency.

- Ensure consistency and compliance across all the plants.

OpenI Advantage

The OpenI team architected the solution by combining multiple innovative solutions. Leveraging its global startup ecosystem, OpenI identified and deployed cutting-edge emerging technologies:

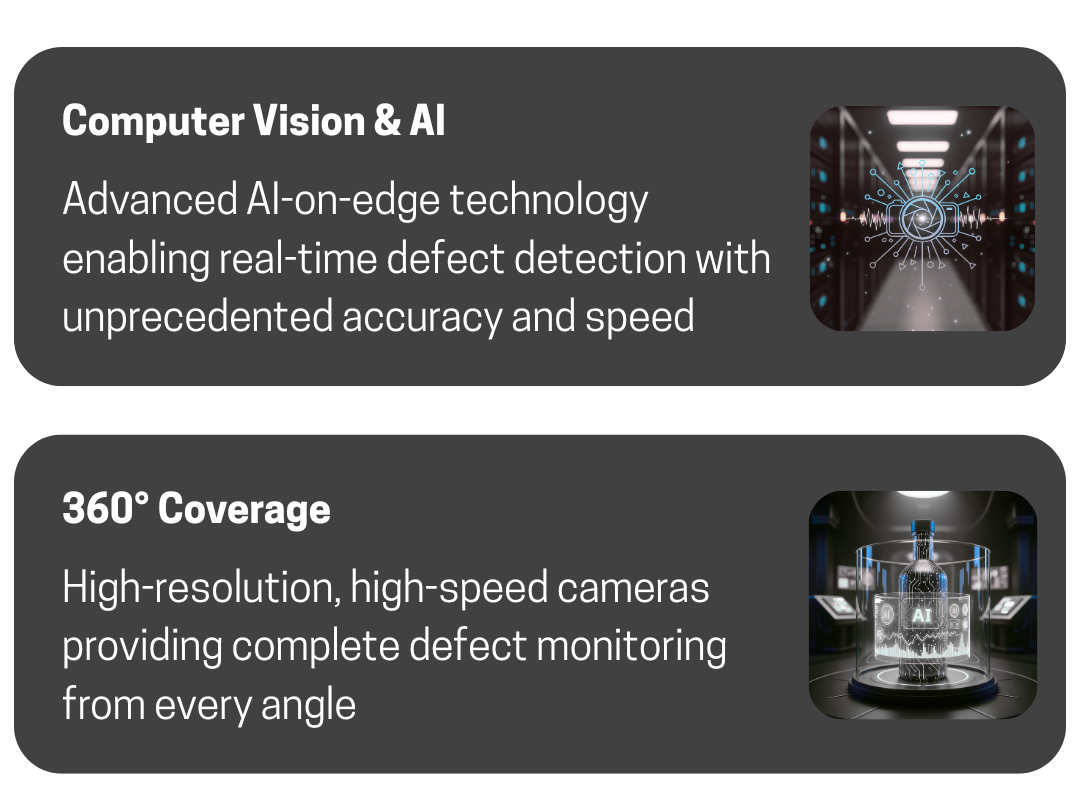

- High FPS cameras to capture moving products on the conveyor belt

- AI-powered edge computing for real-time defect detection and categorisation

- Robotic automation enabling 360° product analysis

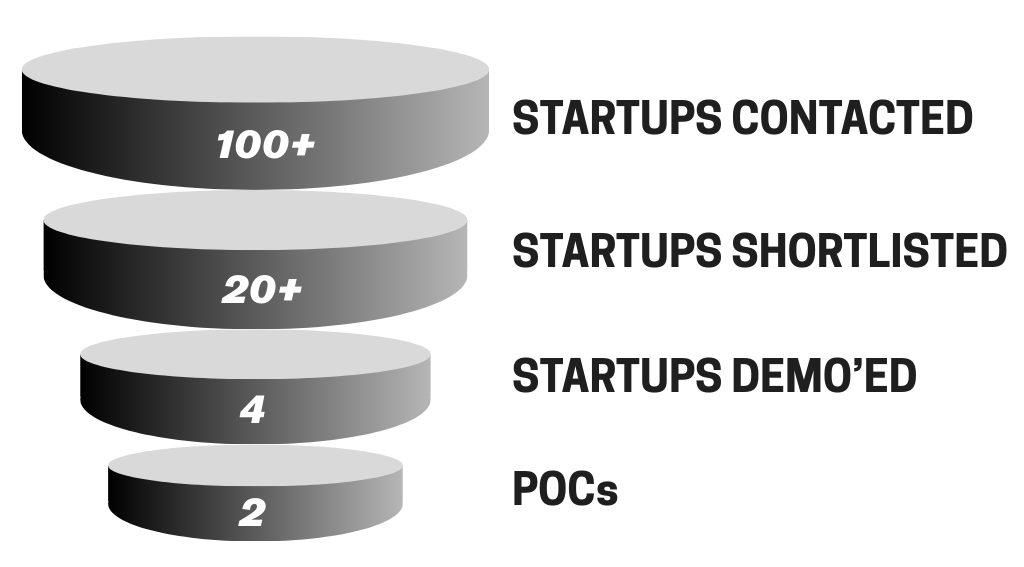

The challenge was launched on the OpenI platform engaging startups, VCs, and accelerators worldwide to scout for the right solutions.

99%

Detection Accuracy

Critical defect identification rate achieved through AI integration

360°

Coverage

Complete bottle inspection with high-resolution cameras

100%

Automation

Fully automated in-line quality control system