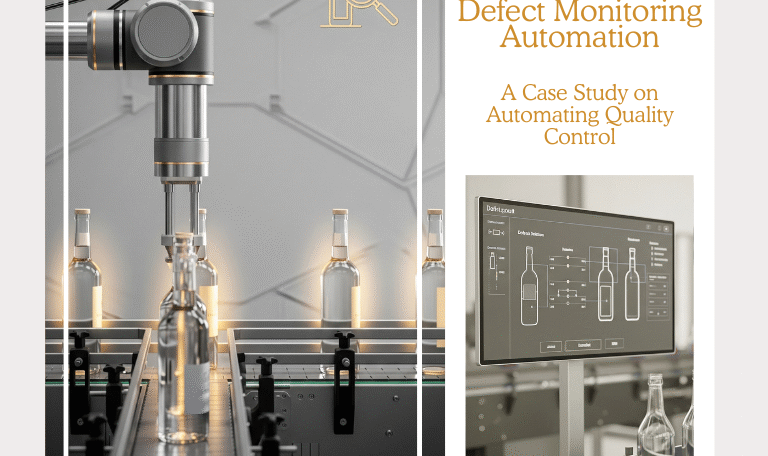

Revolutionising Quality Control with AI-Powered Defect Detection A leading global alcohol beverage company transformed their quality assurance process, achieving 99% accuracy in detecting critical defects through innovative startup-driven solutions to solve manual inspection issues creating significant operational challenges. Key Objectives Automate inspection of liquids, bottles, closures, labels, and packaging. Improve accuracy, consistency, and scalability of..